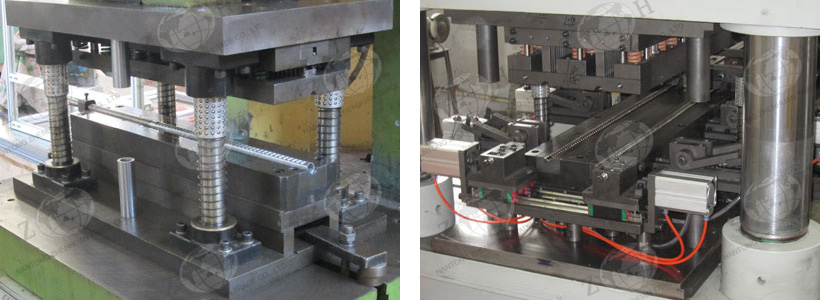

| Item | Data |

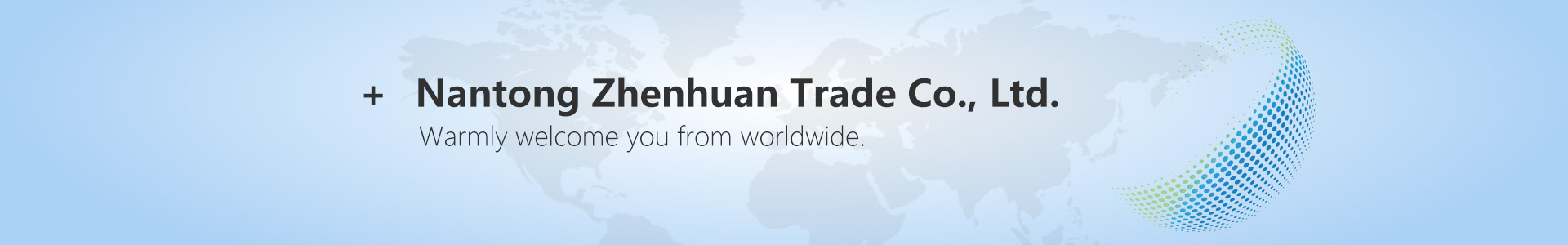

| Machine code | JLG-1 (/JLG-2) |

| Max. working force | 65T (/100T) |

| Pipe quantity can be produced one time | One (/Two) |

| Suitable material | Aluminum or copper |

| Suitable pipe diameter and wall thickness | Φ(20~50)mm x (1.0~1.5)mm |

| Suitable pipe effective length | 200~650mm |

| Pierced slot width and tolerance | 1.0~3 ± 0.03 mm |

| Pierced slot length and tolerance | 16~36 ± 0.03mm |

| Center distance between slots and tolerance | 5~12 ± 0.05mm |

| Production speed | About 20 seconds per pipe |

| Die changing speed | About 30 minutes |

| Hydraulic pressure | 8~21MPa |

| Pneumatic pressure | 0.5~0.8MPa |

| Hydraulic oil | ISO VG32 for winter; ISO VG46 for Summer |

| Lubricant oil | ISO VG22-32 |

| Total motor power | 11.5kW |

| Machine dimension | 2250 x 2080 x 2480mm |

| Machine weight | 4T / 6T |

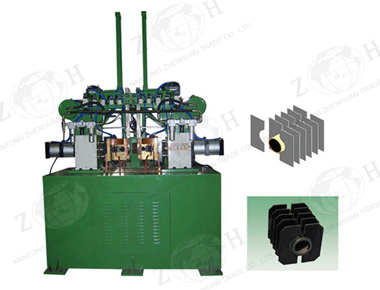

Radiator Fin Rolling Machine

Radiator Fin Rolling Machine Radiator Tank Clinching Machine

Radiator Tank Clinching Machine Copper Tube Manifold Connector

Copper Tube Manifold Connector  Pin Fin Tube Welding Machine

Pin Fin Tube Welding Machine Heat Exchanger Extruded Fin Tub

Heat Exchanger Extruded Fin Tub H Gilled Boiler Fin Tube Weldin

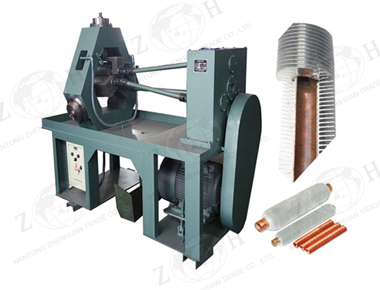

H Gilled Boiler Fin Tube Weldin L Fin Tube Winding Machine

L Fin Tube Winding Machine Copper Tube Collaring Machine

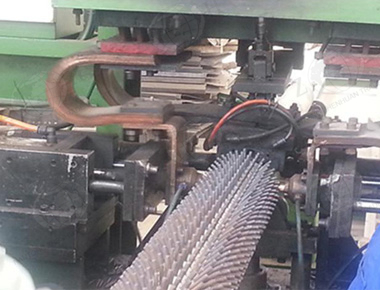

Copper Tube Collaring Machine Microchannel Aluminum Flat Tube

Microchannel Aluminum Flat TubeNo. 243, Ninghai Road, Rugao City, Jiangsu Province, China 226500

+86 13962724758 Franks Cao

+86 13626278212 Aileen Chen

+86 15262775225 Lily Bian

+86 15050633920 Mae Zhang