| No. | Item | Data |

| 1 | Suitable copper alloy | TP2M or TUPY |

| 2 | Suitable copper tube outer diameter | Φ5~Φ16mm |

| 3 | Suitable copper tube wall thickness | ≤1.0mm |

| 4 | Suitable min. copper tube length | 60mm |

| 5 | Suitable max. copper tube length | 800mm |

| 7 | Single action duration | 3~5 seconds |

| 8 | Productivity | 1200-1500 pcs/h |

| 9 | Coaxiality between finished end and tube center | Less than 0.1mm |

| 10 | Out-of-roundness of expanded end | Less than 10% of tube diameter |

| 11 | Mold material | Cr12, quenched HRC 58-62 |

| 12 | Hydraulic pump motor power | 2.2kW |

| 13 | Hydraulic pressure | 6MPa |

| 14 | Pneumatic pressure | 0.4-0.7MPa |

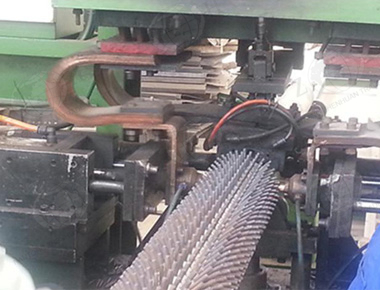

Radiator Fin Rolling Machine

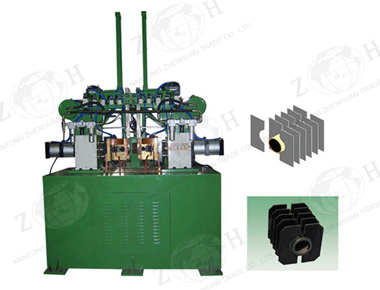

Radiator Fin Rolling Machine Radiator Tank Clinching Machine

Radiator Tank Clinching Machine Copper Tube Manifold Connector

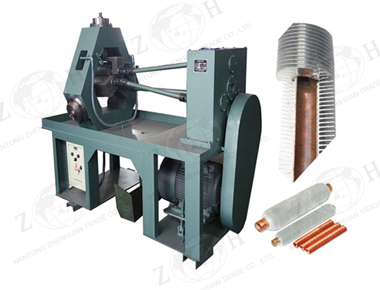

Copper Tube Manifold Connector  Pin Fin Tube Welding Machine

Pin Fin Tube Welding Machine Heat Exchanger Extruded Fin Tub

Heat Exchanger Extruded Fin Tub H Gilled Boiler Fin Tube Weldin

H Gilled Boiler Fin Tube Weldin L Fin Tube Winding Machine

L Fin Tube Winding Machine Copper Tube Collaring Machine

Copper Tube Collaring Machine Microchannel Aluminum Flat Tube

Microchannel Aluminum Flat TubeNo. 243, Ninghai Road, Rugao City, Jiangsu Province, China 226500

+86 13962724758 Franks Cao

+86 13626278212 Aileen Chen

+86 15262775225 Lily Bian

+86 13485105931 Cherie Mao